Machining possibilities are endless when manual machine tools are optimized for quality and efficiency. That’s why manual machine tool operators of all skill levels use the ACU-RITE MILLPWRG2 CNC mill control.

Machining possibilities are endless when manual machine tools are optimized for quality and efficiency. That’s why manual machine tool operators of all skill levels use the ACU-RITE MILLPWRG2 CNC mill control.

The MILLPWRG2 supports professionals seeking higher production, educators inspiring the next generation, and hobbyists pursuing their passions. Keep reading to explore the advantages of machining with a MILLPWRG2 in various manufacturing applications.

What Is the MILLPWRG2 CNC Mill Control?

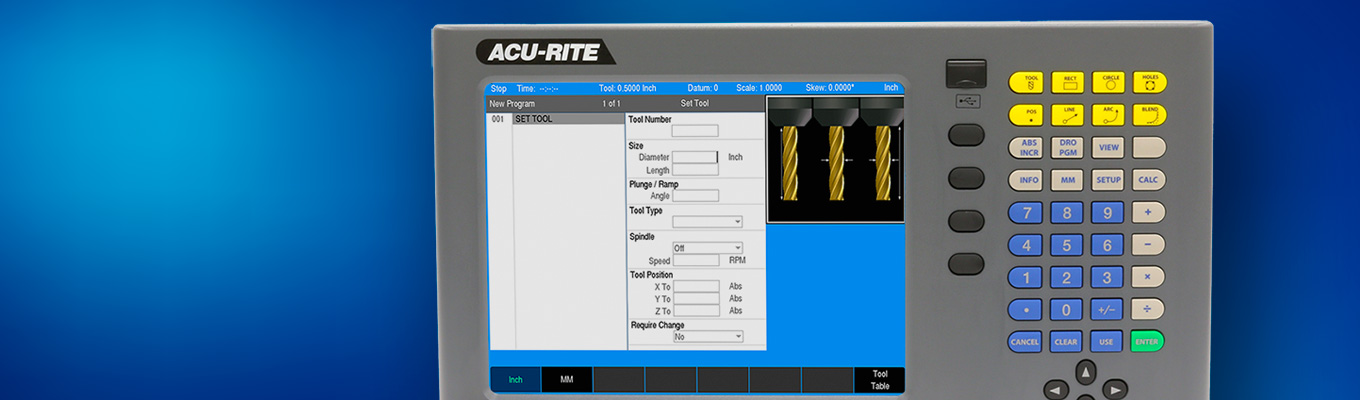

The MILLPWRG2 is an entry-level CNC retrofit system designed, built, and supported in the USA by ACU-RITE. It’s compatible with knee and bed mills with two to three axes.

The MILLPWRG2 is ideal for applications requiring both manual and automated machining. It can operate as a full-function DRO system, a programmable CNC control, or both. Automating manual processes right at the machine eliminates the need for external setups.

ACU-RITE developed its CNC mill control so every manual machine tool operator can quickly learn, understand, and use it—from machining students to experienced machinists. The MILLPWRG2 can also integrate with nearly all the most popular machine brands, new and old.

Why Use the ACU-RITE MILLPWRG2?

The MILLPWRG2 powers precision in every manual milling application, including automotive, aerospace, and beyond. With the ACU-RITE MILLPWRG2 CNC control, users can produce superior workpieces and greater efficiency.

Superior Workpieces

HEIDENHAIN powers the advanced technology of the MILLPWRG2. It enhances machining capabilities and accuracy, resulting in less scrap and tighter tolerances for shapes from simple to complex.

- Real-time Feedback: MILLPWRG2 achieves greater consistency and fewer mistakes because it provides accurate real-time feedback on tool positions and movements.

- 3D Graphics System: The 3D graphics system also improves accuracy. Users can program cycles using conversational language prompts. Plus, they don’t need multiple screens, thanks to the streamlined navigation.

- Resolution and Repeatability: Precision and consistency are essential for quality control in machining. When paired with an ACU-RITE linear encoder, the MILLPWRG2 produces repeatable precise measurements.

Greater Efficiency

The MILLPWRG2 is durable. Many customers who purchased a first-generation model are still using it decades later. The CNC mill control can maximize machine lifespan and throughput, increasing efficiency and profitability.

-

- Programmable Tool Paths and Memory Recall: The MILLPWRG2 saves time in setting up and executing machining operations for repetitive tasks and complex patterns. Users can program common features, create programs from existing parts, input part geometry from a CAD file, and display estimated runtime.

- Retrofitting Capabilities: The MILLPWRG2 is compatible with 100+ machine makes and models. When upgraded with the MILLPWRG2, existing mills gain a longer lifespan and more capabilities without a significant investment.

- Durability: The MILLPWRG2 performs consistently over time, saving time and resources associated with repairing and replacing equipment. Its components are designed, manufactured, and tested to withstand even the harshest machine shop environment.

How Do Machining Professionals Use the MILLPWRG2?

Machining professionals rely on the MILLPWRG2 CNC mill control to tackle a range of manufacturing challenges. The MILLPWRG2 empowers machinists, engineers, job shop owners, and other professionals involved in manual machining with greater precision, efficiency, and innovation.

Application #1: Replicating Classic Aircraft Parts

Burl’s Aircraft, LLC has manufactured parts for classic and current aircraft using a first-generation MILLPWR since 2000. Based in Chugiak, Alaska, Burl’s creates FAA-approved components for engine mounting brackets, landing gear, flight control surfaces, and more.

The MILLPWR helped Burl’s upgrade its capabilities to machine “basically anything” with a shape to it, including some parts that have to be regenerated from drawings.

Application #2: Solving Today’s Manufacturing Challenges

The Oregon Manufacturing Innovation Center – Research & Development (OMIC R&D) is home to a MILLPWRG2. OMIC R&D is an advanced manufacturing research center that provides applied research and advanced technical training.

OMIC R&D relies on the ACU-RITE CNC mill control to help develop new tools, techniques, and technologies to address manufacturing challenges.

Application #3: Prepping TEAM USA Luge Sleds for Competition

As the fastest sport in the Winter Olympics, luge relies on precision for optimal speed and safety. The USA Luge Association uses a MILLPWRG2 to create high-precision parts and components for TEAM USA luge sleds.

With the MILLPWRG2, USA Luge can machine complex molds and rapid prototypes in-house, improving efficiency. USA Luge also uses the tool’s “Teach” feature, which creates programs from existing parts.

What Are MILLPWRG2 Applications in Education?

The MILLPWRG2 is an effective tool for educating the next generation of machinists and engineers. Educators use it to teach CNC machining and facilitate hands-on learning in community colleges and university engineering labs. The user-friendly interface and robust capabilities enable students to execute their ideas with precision and efficiency.

Application #4: Educating Students in CNC Machining

The MILLPWRG2 helps students at Guilford Technical Community College (GTCC) transition from manual to CNC machining. GTCC, located in Jamestown, North Carolina, uses 18 MILLPWRG2 systems in its Computer-Integrated Machining program.

GTCC chose the MILLPWRG2 because they’re easy for students to learn and use. Students can download programs via flash drives, write programs away from the machine, and translate their ideas to tangible objects efficiently and effectively.

Application #5: Developing Student Prototypes

The Biomed Engineering Lab at the University of North Carolina (UNC) exposes students to CAD and fabrication, including milling using the MILLPWRG2. The CNC mill retrofit teaches the fundamentals of machining and conversational programming. It also allows students to develop prototype parts.

One UNC biomedical graduate student designed a microfluidics fixture with small acrylic tracks to measure the characteristics of small-scale fluid flow. When laser cutting didn’t produce the desired outcome, the student programmed and produced their design on the MILLPWRG2, enabling progress with their research.

How Do Hobbyists Use the MILLPWRG2?

Hobbyists nationwide use the MILLPWRG2 to execute their visions more precisely and efficiently. It facilitates rapid prototyping, intricate machining tasks, and higher levels of creativity.

Application #6: Crafting Custom Parts for Modified Classic Cars

A master tool-and-die maker has teamed up with a retired high-tech industry executive to build custom parts for street and hot rods using a MILLPWRG2. The CNC mill control enables the pair to produce one-of-a-kind components affordably.

A recent project involved machining custom rear axle knuckles. They were used to adapt a 1996 Corvette independent rear suspension assembly to a 1955 1/2-ton pickup truck.

Application #7: Creating Tattoo Machine Prototypes

A former U.S. military machinist and welder uses the MILLPWRG2 to keep up with the demand for his tattoo machines. Dan Kubin builds about 50 tattoo machines a week, typically selling out the day he posts them on his website.

Kubin uses the MILLPWRG2 for rapid prototyping, which boosts his efficiency and cost savings. He draws up his idea in CAD and then uploads a DXF file to the MILLPWRG2. Now, his prototyping process is faster and better accommodates creative changes.

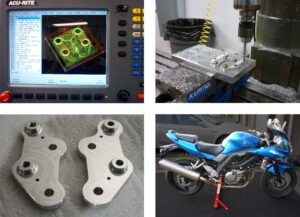

Application #8: Making Custom Motorcycle Parts

Craig Guth has used his first-generation MILLPWR since 1996. He makes custom motorcycle parts from home for sale and for himself, including front-end parts, triple trees, and wheels. But the CNC mill retrofit also helps Guth bring other big ideas to life.

Guth used his MILLPWR to create a computer box resembling aircraft landing gear for a computer manufacturer. A photo of his creation appeared on the cover of Computer Power User Magazine in 2008. He also created a 60”x50” CNC wood router for his home shop that consists of complex patented machined parts.

Transform Your Manual Machining with the MILLPWRG2 CNC Mill Control

The ACU-RITE MILLPWRG2 CNC control is a versatile solution for improving manual milling operations in various industries. It has helped thousands of manual machine tool operators optimize their processes while saving time and cost.

Could your manual machining operations benefit from greater quality and efficiency? Whether you’re a seasoned professional, an educator, or a hobbyist in machining, the MILLPWRG2 CNC mill retrofit can transform the precision and productivity of nearly any mill.

Request more information about the ACU-RITE MILLPWRG2 CNC control.