The TURNPWR lathe control

TURNPWR is a workshop-oriented turning control that enables the user to program conventional machining operations right at the machine. It is designed for turning machine tools with up to two axes. TURNPWR was developed to satisfy the wants and needs of lathe machinists where manual and automated operation are both useful and needed. TURNPWR promises to enable the user to maximize throughput by significantly reducing setup time, scrap and other non-productive operations.

TURNPWR support

Want More Information?

Enter your contact information and we'll get back to you as soon as possible.

Conversational programming

The well-known ACU-RITE conversational programming format for controls is a user-friendly method of writing part programs and included in the TURNPWR, however G-code (ISO) programming can also be used. Basic editing of G-code programs is also possible.

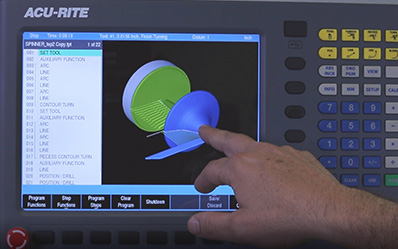

Large high-resolution display

A 12.1" high-resolution display boasts a screen layout that is clearly arranged and user friendly. You can preview graphics in the editor and illustrate individual machining steps and corresponding tool path when programming contours, using only dimensions pulled from a production drawing. DXF files are also compatible.

Position-Trac™

TURNPWR is a closed-loop system with positioning feedback provided by rotary encoders inside the motor assemblies. When fitted with the (optional) ACU-RITE precision glass scales (1 µm/0.00005" resolution), TURNPWR also includes Position-Trac™, an advanced feature that enables the user to easily, quickly and accurately re-establish work piece zero after shutting down or power loss.

See the TURNPWR in action

Frequently Asked Questions

How does the TURNPWR differ from other lathe controls?

While our DROs offer the basic foundation, TURNPWR provides an entry level turning control solution. ACU-RITE offers a complete turning solution, from the ground up, making the transition from readouts to controls quick and simple.

Is the TURNPWR compatible with all lathe machines?

The versatile TURNPWR is compatible with nearly all of the most popular machine brands, new and old.

Specifications

| DRO Mode | • Multiple Datums (Fixture Offset): 99 • Zero Reset • Near Zero Warning |

|

| PGM Mode | • Thread Cycles, Recess Cycles, Turning Cycles • Position / Drill, LINE, ARC, BLEND (Blend / Chamfer) • Estimated Machining Time • View Graphics: 2D Line / 3D Line / 3D Solid • Block Form w/ User Override • Replication (Repeat) • Comment Step - Event comments • Program Manager Navigation Tree w/ Program Type Filter • Long Program Names • Program Preview: Listing & Graphic w/ Estimated Machining Time • Explode Step: Repeat |

• Reverse (Step / Path) • Shift Steps • Auto Save (Program) • Program Size Limit (TPT only): 9999 Steps • DXF File Import • G-code Program: w/Graphics Support / Simple Edit • On-Screen Help: User Manual Viewer (Text & Graphics) • Parts Counter & Clock • Optional Stop (G-code Only) • Feed Override: Potentiometer • Error Compensation: Linear & Bidirectional Non-linear |

| Processor | 1.4 GHz Dual Core Celeron® Processor | |

| Display | 12.1-inch 1024 x 768 Color LED | |

| Internal Storage | 2.5 GB CFAST (SATA) User | |

| Remote Handwheel | Standard with AC kits | |

| Housing | Die Cast Metal Bezel & Enclosure (Back Sheet Metal, Kit Style Console) | |

| Connections | Ethernet, USB (x2) | |

| Accessories | • Linear Feedback • Electronic Edgefinder • Offline Software |

|

| Weight | ~7.7 kg | |

| Electrical Requirements | AC 100 V to 240 V (±10 %), 50 Hz to 60 Hz (±2 %) | |

| Operating Temperature | 0° to 45º C (32º to 113º F) | |

| Storage Temperature | -20º to 70º C (-4º to 158º F) | |

| Protection | IP 54 (Front) / IP 40 (Back) (Kit Style Console) | |